Model-based design expands to model visualisation and quality assurance

At Destia, model-based design forms the basis for the implementation and quality assurance of infrastructures, but also for maintenance digitalisation – in a broad sense, it is the backbone for the operations of the entire company.

Model-based visualisation and production quality assurance are now being developed for this entity.

“Model-based design and its visualisation are well advanced, especially when it comes to road operations, i.e, the design and execution of roads, streets and areas,” says Development Manager Olli Planting of Destia’s Design Services, where he is responsible not only for developing software and operational methods but also for data model coordination and road design.

“The above naturally also applies to the design and execution of structural engineering structures, such as bridges, retaining walls and other structures required on the road and street network.”

Visualisation for geotechnical and environmental structures

This year, Destia has also invested in the visualisation of 3D models used in geotechnical and environmental design. We want to present the customer with as authentic as possible a view of the planned solution. For designers, visualisation is enjoyable work.

“We can make a high-quality presentation video of the designed object, such as a centrally located park or street in the city, for example, for public events,” Planting says.

“Customers are increasingly asking us questions about visualisation, and we are responding to this need with new tools, i.e with high-quality illustrations and videos based on model-based design.”

Model-based quality assurance to support geotechnical design is also being developed with the customer. In road design such a solution is already in use.

“From the visual model, it is easy for the customer to check the plan before approving it. It is a big step forward, because, so far, geotechnical plans have been inspected from 2D drawings.

A link from machine automation to supervision

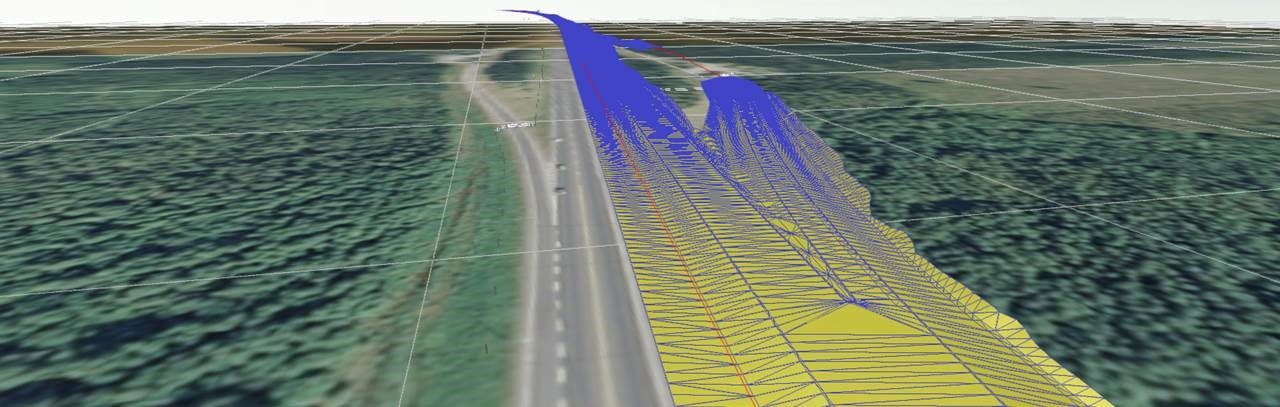

Reviewing model-based designs works well in, for example, ‘design and build’ projects. The approved model can be transfered to Destia’s construction unit, which will then utilise it in model based production process using work machine automation.

“Once the model is loaded onto the machine’s automation application, the machines can implement the surface to be built with centimetre-level accuracy.”

Actual data on the final product is automatically uploaded to Destia’s and its customers’ shared platform.

“Through the shared platform, designers, builders, customers, external quality controllers and other project stakeholders can monitor the quality measurement performed by work machine automation in real time and determine whether the built surface corresponds with the planned surface.”

This allows for both high quality and transparent construction.

“The customer always sees what is being built and what is the end product of the construction. They don’t need to guess whether the contractor is actually building what he has promised to build,” Planting says.

Modelling allows for a more accurate cost estimate

Modelling produces relatively accurate volume and area quantities based on which a fairly accurate cost estimate can be calculated. Mass efficiency increases and the contractor can tender with a smaller risk reserve.

– Correspondingly, in the construction phase, when the contractor takes the actual measurements of the built surface, it is possible to calculate the exact realised quantities in area and volume.

Towards a comprehensive status overview

Shared platforms support customer collaboration. Through the platform, both the customer and other construction parties can independently study the input data and design models during the project.

“The new technology provides a comprehensive overview of the area to be planned and built. The terrain can be mapped with 360 cameras and drones, for example, and all this information can also be seen and utilised by the customer.”

“We have acquired drones that use high-precision real-time kinematic measurement (RTK) technology, which is combined with laser scanning and aerial photography data with the accuracy to a few centimetres”.

RTK drones are utilised in ‘design and build’ projects, among other things, when you want to know the state of construction at any given time.

“With a drone, we can fly through the construction site once a week, for example, and produce data for the customer. For example, aerial photography supports planning and supervision during work exceptionally well,” describes Planting.

Designers, too, visit sites

Especially in ‘design and execute’ projects for large and demanding sites, designers can be placed on site in the Big Room workspace.

“According to the experience gained from design and build projects, the designer’s presence on the site together with the constructor improves the quality and speed of the design.”

Planting himself has worked as a designer and BIM coordinator for the Oulu motorway follow-up project “Improvement of National Road 4 between Kello-Räinänperä”.

“It has been the best project of my career so far. Together with the constructor, we got to think about the best possible solutions by the pit, Planting explains.

Planting sees Destia’s great strength to be that, under the same roof, you can find all the necessary execution options for the life cycle of the infrastructure, from design to maintenance.

“The close co-operation between design and construction on design and build projects enables an efficient and controlled quality assurance chain from one stage of work to another, which produces high-quality construction.”

Competence is maintained through training

Olli Planting considers the way that Destia takes care of accumulating and maintaining expertise to be excellent.

Know-how is maintained through, among other things, in-house training plans and programs. Exemplary efforts are being made especially in inducting newcomers and investing in the adoption of information.

“The training of a new employee is shaped according to their future job. In the design unit, we have training packages for design applications that can be reviewed.”

The practices in the field of model-based design can also be taught to a new designer.

“External service providers will also be used to support the induction of a new employee, if necessary.”